The Fully Automatic Block Production Line with curing rack is another popular production line, and it is very fit for large and super-large block factory.

The blocks can be cured very fast and very conveniently with the production line.

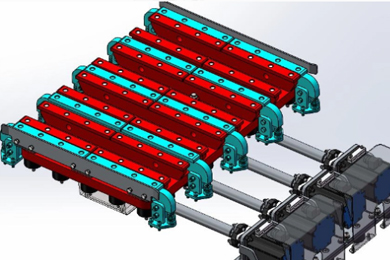

The production line includes: automatic raw material system, the automatic block machine, the automatic transferring system, and the automatic curing system.

In addition to, the finished blocks will be top quality, because the automatic curing system

The block machine adopted: T13,T15,T18,T20

Advantages:

1. High flexibility: The modular design and layout can customize the required products according to the needs to meet personalized needs. For example, the stacking system and the forming system can operate independently or in series to add a multifunctional automatic board return system.

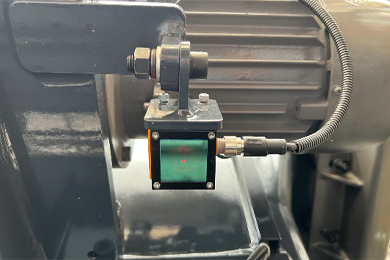

2. High degree of automation: The floor space is reasonably regular, the degree of automation is high, and the production line is fully configured to achieve automated production.

3. Low investment: There is no need to build a curing kiln in the curing area, and the infrastructure investment cost is low.

4. Improve quality Storing: with a curing rack avoids the contact between the pallet and the upper part of the wet blank, increases the contact area between the wet blank and the air, and has a better curing effect, which is conducive to making high-quality bricks.

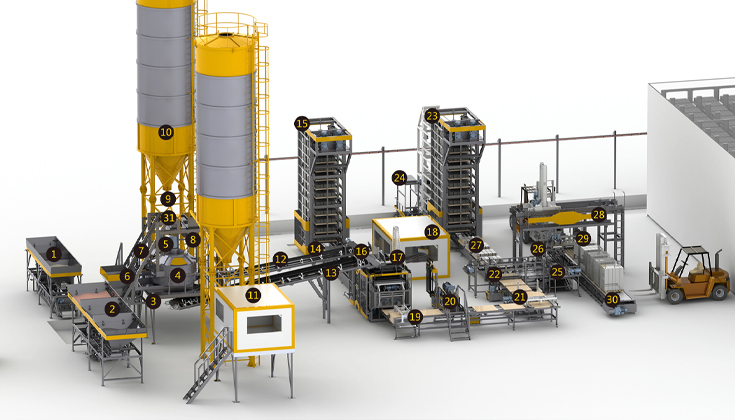

| 1. Pigment batching machine | 2. Base batching machine | 3. Mixing platform | 4. Concrete mixer | 5. Pigment mixer | 6.Concrete mixer hoist |

| 7.Pigment mixer hoist | 8. Base cement scale | 9. Screw conveyor | 10. Cement silo | 11. Mixing system control room | 12.Belt conveyor for pigment |

| 13.Belt conveyor for raw material |

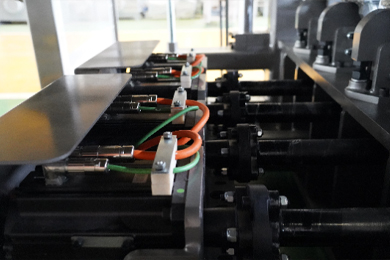

14. Wet block conveyor |

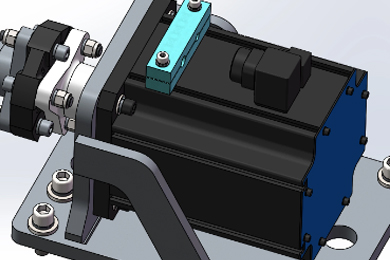

15. Elevator | 16. Auto.color-feeding system | 17. Block making machine | 18. Center control system |

| 19.Horizontal pallet feeder | 20. Pedestrian bridge | 21. Pallet turnover machine | 22. Chain type block pusher (horizontal ) | 23. Lowerator | 24. Program-controlled finger cart |

| 25. Chain type block pusher (longitudinal) | 26. Rotary table for grouping block | 27. Cured block conveyor | 28. Palletizer(Cuber) | 29. Tray bin | 30. Finished product conveyor/tank-type conveyor |

| 31. Pigment cement scale |