The automatic block production line including the automatic raw material supplying system, automatic block machine, but excluding the automatic cubing system, the block curing system.

The automatic block production line is very fit for medium and large block factory. In addition to, the production line is low cost, and can operate by several workers.

The block machines can be adopted: T10, T12,T13,T15 block machine

Advantages:

1. Compact and reasonable layout: Small footprint, compact layout, and small production workshop required.

2. High adaptability and good scalability: The back end can be equipped with high/low block collection lines, and can also be expanded to a production line with a higher degree of automation.

3. High reliability and flexibility: The system is simple, with stable and reliable performance; modular design and layout, the required products can be customized according to needs to meet personalized needs.

4. High economic applicability: Small investment, high return.

| 1. Batching Machine | 2. Concrete Mixer | 3. Cement Scale | 4. Screw conveyor | 5. Cement Silo | 6. Automatic Pallet Provider |

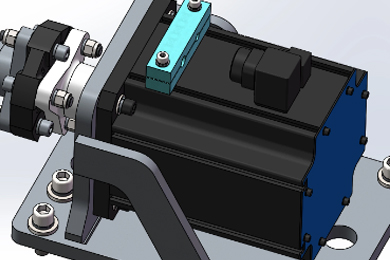

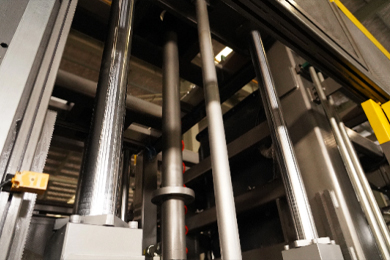

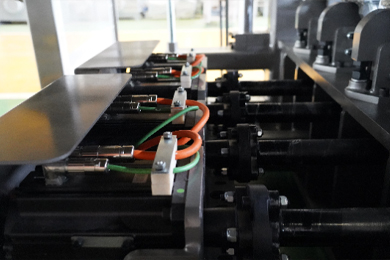

| 7. Belt Conveyor | 8. Pallet Feeder | 9. Block making machine | 10. Hydraulic Unit | 11. PLC Control Unit | 12. Auto. Color-Feeding System |

| 13. Block Conveyor |

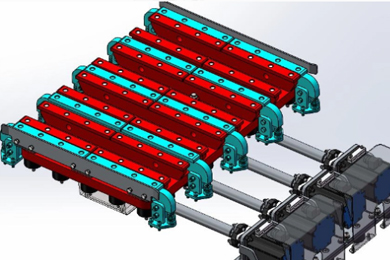

14. Block Stacker |

15. Belt Conveyor For Pigment | 16. pigment screen | 17. Pigment Mixer | 18. pigment mixer hoist |