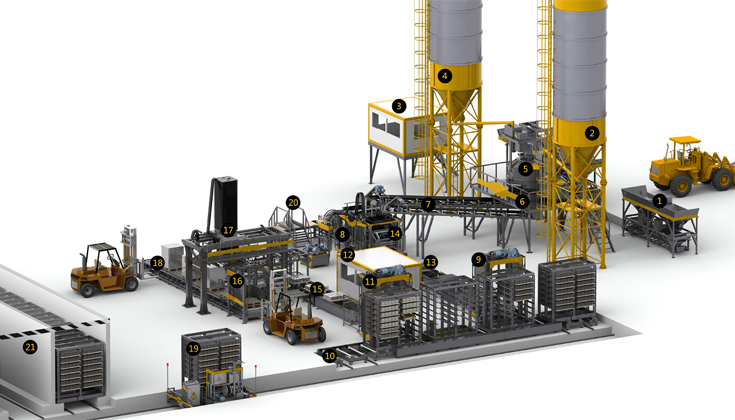

As the most popular production line, it is adopted by most of our customers.

The production line is fully automatic, because it adopts automatic raw material system, automatic block machine, automatic cubing system, and automatic curing system.

It will need only 4 workers to operate all the line, and will make more money for the customers.

The fully automatic production line is fit for large and super-large block factory.

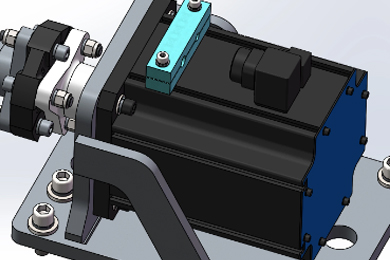

The block machine adopted: T13,T15,T18,T20

Advantages:

1. High flexibility: modular design and layout, can customize the required products according to demand to meet personalized needs.

2. Reduce investment costs: equipped with automatic metering, mixing, automatic conveying, transfer, automatic storage, automatic grouping, stacking and other fully automatic production lines, greatly reducing labor input and costs.

3. Save space, high-position curing kiln: save wet blank curing space, make greater use of the site, and avoid contact between the pallet and the upper part of the wet blank, increase the contact area between the wet blank and the air, and achieve better curing effect, which is conducive to making high-quality bricks.

4. Complete equipment: reasonable and regular space, high degree of automation, complete production line configuration, can realize automated production.

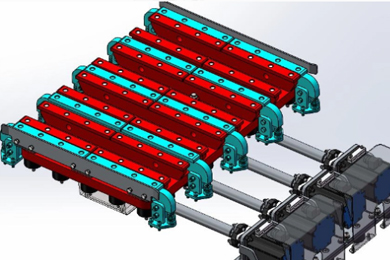

| 1. Automatic Batching Machine | 2. Cement Silo | 3. Mixing System Control Room | 4. Cement Silo | 5. Mixing System | 6. Mixing System Platform |

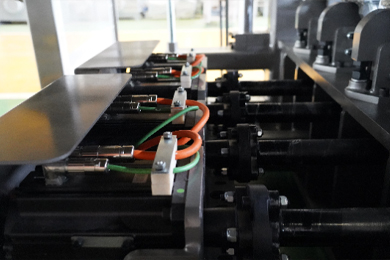

| 7. Belt Conveyor | 8.Block Making Machine | 9. Elevator | 10. Curing Rack Conveyor | 11. Lowerator | 12. Central Control System |

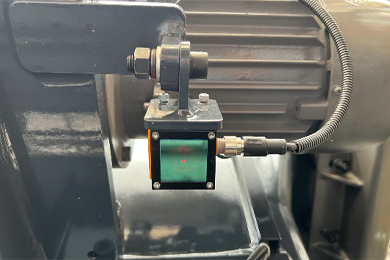

| 13. Block Conveyor |

14. Auto. Color-Feeding System |

15.Circulation Conveying System | 16. Tray Bin | 17.Palletizer(Cuber) | 18. Chain Conveyor |

| 19.Finger Cart For Curing Rack Transfer Conveyor | 20.Pedestrian Bridge | 21.Curing Kiln |