QT4-35 Brick Machine Shipped to Uganda with Full Trial-Run Verification

Compact machine shipped via consolidation—customer approved photos, videos, and dustproof packaging before dispatch

.jpg)

.jpg)

.jpg)

Shipment Date:

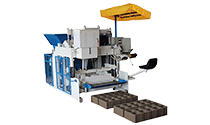

Product: QT4-35 Semi-Automatic Brick Machine

Shipping Method: Consolidation (LCL)

Transparent Pre-Shipment Process

Before dispatch, we carefully wrapped the QT4-35 brick machine in dustproof film, counted all components, and affixed labels according to the customer’s specifications. We then captured high-resolution photos and a trial-run video and sent them for final confirmation.

Only after the customer approved everything did the logistics company collect the goods. Due to its compact size, the equipment was shipped via consolidation (LCL)—transported to the port and loaded onto a shared container vessel.

Complete Brick Production Line

The QT4-35 is a full set of equipment including:

- Batching machine

- Mixer

- Belt conveyor

- Block forming machine

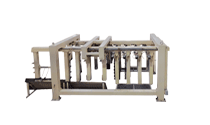

- Stacking system

It produces high-strength concrete bricks for housing, road paving, and infrastructure. Our bricks are known for durability and long service life—making them highly popular in local markets.

Advanced Technical Features

Our brick machines are engineered for reliability and efficiency:

- Customizable electrical systems: Siemens or Schneider PLCs, frequency converters for motor protection

- Reinforced molds: Heat-treated and liquefied for 60% higher strength

- 360° multi-axis rotary feeding system: Ensures uniform material distribution and superior brick quality

- Taiwanese hydraulic proportional valves: Protect hydraulic cylinders and extend machine life

Price range: US$9,000 – US$160,000, depending on configuration.

From Manual Labor to Profitable Automation

Previously, the customer made bricks by hand—a slow, labor-intensive process. With the QT4-35 semi-automatic machine, they can now:

- Save significant manpower

- Increase daily output

- Produce higher-strength, marketable bricks

The customer was extremely satisfied and eager to start production upon arrival. As a company with decades of export experience, we provide truly worry-free service: “After payment, just wait for the machine—and start making money.”

We look forward to the next update from Uganda!