Custom 75m³/h Concrete Batching Plant Delivered to Samoa

Replacing outdated system with reliable, high-efficiency solution backed by 41 years of engineering expertise

Delivery Date:

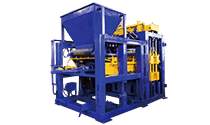

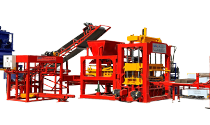

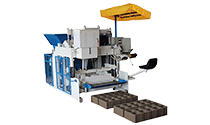

Product: Stationary Concrete Batching Plant

Capacity: 75m³/h (Theoretical)

Key Feature: Full customization + 3-day spare parts delivery

Replacing the Old, Building the Future

On November 14, 2025, Linghao Machinery successfully delivered a customized stationary concrete batching plant to our valued customer in Samoa. This new 75m³/h plant will replace their outdated system, significantly improving production efficiency, concrete quality, and operational reliability.

Complete, Integrated Plant Design

The plant includes all essential components for high-grade concrete production:

- Concrete batcher

- Belt conveyor

- High-performance concrete mixer

- Patented control system (easy operation)

- Cement silo with screw conveyor

It can produce various concrete grades for high-rise buildings, bridges, tunnels, and infrastructure projects—making it a cornerstone of modern construction.

Why Samoa Chose SANQGROUP

- ✅ 41+ years of continuous improvement – ensuring unmatched reliability

- ✅ Fully customized to site layout, power supply, and local requirements

- ✅ Patented control system for intuitive, stable operation

- ✅ Factory-direct pricing – more than 15% below market average

- ✅ Free spare parts for 1 year + 3-day delivery from our dedicated warehouse

The customer highly appreciated our professional team’s thorough discussion on layout, power, electrical components, delivery, and control systems.

Want a Perfectly Matched Batching Plant?

Please provide the following information so we can design the ideal solution for you:

Your Requirements:

- Required capacity (e.g., 50m³/h, 120m³/h) – we’ll recommend the right model

- Available plant area size – we’ll optimize layout and machine selection

- Preferred electrical brand – Siemens, Schneider, Chint, or others

- Any other customization needs (e.g., dust collector, aggregate type, automation level)

With decades of global experience, Linghao Machinery delivers not just equipment—but peace of mind.